Rough Framing: Solidity in Construction Procedure

Introduction to Rough Framing

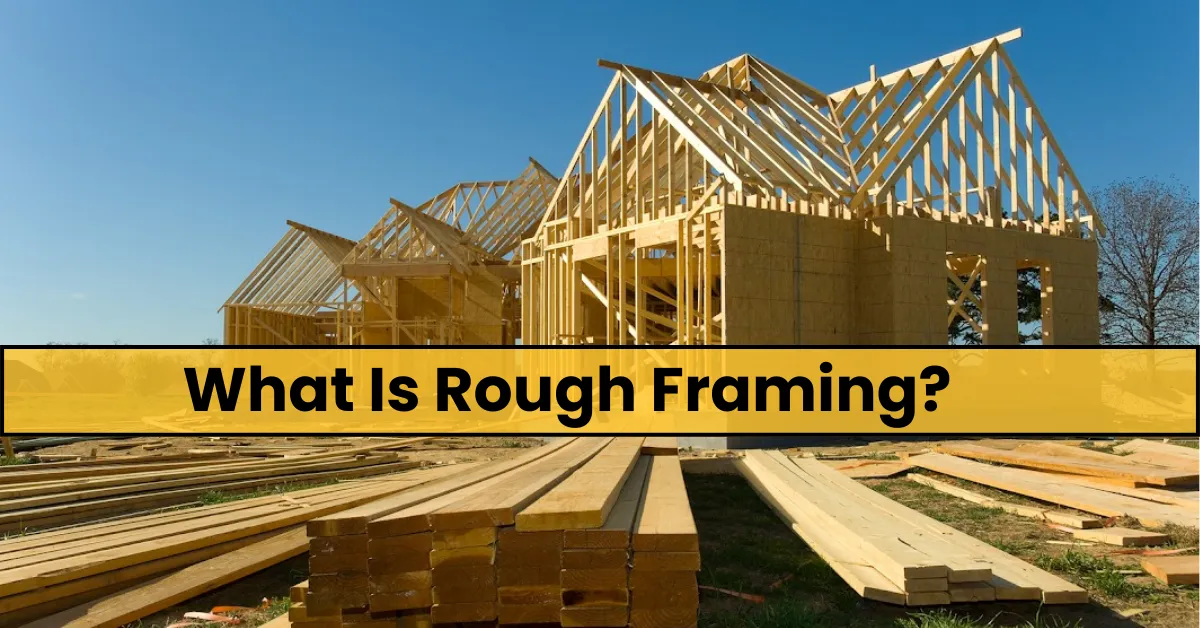

Rough framing, or rough carpentry, is the framework for building construction. This means it involves creating the building’s structure, which may include the walls, roofs, floors, etc. The entire building, in essence, is given an outline and support through the framing, and all other components, including electric work, insulation, and plumbing, have a base.

This process involved laying down new buildings and giving additional room to all the existing ones. The size and shape of rough framing are also crucial to constructing the building’s framework. It also has to be concrete enough to carry the weight of everything that would be added to it.

Understanding of Rough Framing in Construction

Rough framing is the structural stable framework of a building. It is what gives a visual image, shape, and dimension. This framework supports all other constructions. Its aspect is that it grants stability and durability to the building.

Only professional contractors and building construction workers rough-build buildings or houses. It is very skilled and experienced people; they know their work, with no mistakes, and have the guarantee that the structure will be stable and of good quality for further addition.

Parts of Rough Framing

- Stud

- Joists

- Rafters

- Headers

- Sheathing

Types

Platform Framing

This type of framing, or balloon framing, is one of the most extensive uses in residential construction. It is essential as it provides fire resistance between floors.

They are easy to construct and provide the flexibility needed for change in design.

Balloon Framing

This old framing technique employs an uninterrupted stud from the foundation up to the roof. To this date, this method is very rarely discussed because of the risk of fire hazards. It offers a robust and uniform structure with few horizontal joins.

Timber Framing

This framing employs the traditional joinery method with large wooden beams without mental holds. Exposed beams can be used to create a design appearance for the floor. It is vital, permanent, and ornamental, used mainly in upscale practices and even in old structures.

Post and Beam Framing

They are much like timber framing, except this system contains fewer large vertical posts and beams. It also includes vertical posts and horizontal beams and often has metal connectors.

It offers more open space for designs that do not have structural load walls inside, making it possible to design in many ways.

Steel Framing

This is a type of framing in which steel studs and joists replace the timbers. Steel framing is mainly used for commercial and industrial buildings. These framing are fire-resistant and termite-proof, very tough.

Hybrid Framing

Using steel sub-frames, We combine several techniques to give instant timber framing. Hybrid framing combines the best of each material to provide an average blend of strength, lower cost, and much more design flexibility.

Significance in Construction

Sometimes called the “bone of construction,” rough framing may be considered the supporting structure the whole building supports.

Structural Integrity

Among the most critical components in building construction is structuring a framework, which can be achieved through rough framing. The first draft of the structure carries all loads inside the building.

In such a case, studs, joists, rafters, and beams are installed to take the structural loads equally so that such problems as sagging floors, bowing walls, or collapsing roofs do not arise. With a strong skeleton, the buildings will be firm enough to withstand environmental stresses and daily usage.

Defining Spaces

Rough framing provides the dimensions of different rooms and spaces in the building that can be experimented with.

This enables one to set all walls, windows, doors, and opening locations ahead of finishing work that may begin while letting the builder and occupants view the general structure before commencing that work.

Efficiency and Flexibility

Rough framing accelerates construction because it offers a prominent and structured framework. Such efficiency tends to mean less chance for errors and rework, hence saving time and money.

It also allows flexibility if changes or adjustments become necessary; it would be easier to make them now than after finishing all the work already done. This kind of allowance for flexibility is critical in dealing with unforeseen problems and design changes.

Quality of Strength and Durability

Since all the framing members would be aligned, anchored, and braced in place, a good quality base is provided at the rough framing to help them endure stresses and loads over time. This is important for the safety and comfort of the building occupants.

Cost Savings Appropriate

Improved to the surface, good roughing can provide benefits for years in the future. Procrastinating with problems saves time and resources because expensive repairs and rework will wait until a builder catches those issues early. Structural defects are unlikely to occur in a solid, stable structure, saving it from costly remedial or renovation work.

Procedure for Rough Framing

Some of the significant steps that imply preliminary and actual farming are involved in making the structure precise, stable, and strong.

Planning and Designing

An intricate blueprint developed by architects and engineers forms the foundation for the approximate framing process that gives the building’s dimensions, layout, and structural requirements to be erected.

Preparation of The Foundation

The site is cleaned and leveled before a building is constructed. A rigid concrete foundation is provided to sustain such a structure. The kind of foundation depends on the design of the building and the condition of the soil.

The most common foundations are concrete slabs or pier-and-beam foundations. A level and stable foundation is indispensable to the longevity and stability of the whole structure.

Wall, Floor, Roof Framing

After laying a foundation, vertical studs and horizontal plates, which form the skeleton of the wall, must be erected and installed.

Depending on the design, these studs should stand 16 or 24 inches from the wall and be held by top and bottom horizontal plates. The floor framing process uses joists, which help form floors from the exterior wall and support interior beams and walls.

Rafters or trusses are positioned atop the walls as the shape and slope of a roof, erected beams that open from the top of the walls to the roof ridge, providing the roof’s angle. Trusses are used for greater strength, orientation of elements, and burden translation while building roof structures.

Utility/Openings

This is the stage where the construction allows an opening for electric wiring, plumbing pipes, and HVAC ducts. This will ensure all utility systems can be fitted later without damaging the building’s structure.

Quality Control/Inspection

Every point in this rough framing stage is carried out with proper checks and inspections so that the work meets the specifications and building regulations. Irregularity or deviation will not be tolerated in order not to allow the compromised integrity of the structure.

Construction Estimation Cost

Several components comprise a takeoff service and an estimate of rough framing cost. These generally include:

Materials:

Timber will constitute the highest cost element. Once again, the price depends on the type of wood and market conditions.

Hardware:

- Nails, screws, connectors, all kinds of clips, etc.

Sheathing:

- Plywood and OSB sheets for wall and roof covering.

Labor:

Skilled Labour

- Experienced as well as efficient carpenters and framers.

Unskilled Labour

- General laborers clean up the site and handle materials.

Overhead

- Project management cost, Permit, and insurance.

Design Complexity

Custom designs require much time and skill, which takes labor costs.

Standard Designs

- Pre-designed plans will be less costly and take less time to operate.

Location

Regional Costs:

- Labor and material cost differences vary from region to region.

Transportation:

- Materials are taken to the site.

Conclusion

Rough framing is part of the building process that gives buildings of all kinds the needed support and framework. Knowledge about the forms of rough framing, its advantages, and the whole process it entices helps homeowners, builders, and architects know what to expect and make the right decisions to ensure their projects succeed.

Whether wood, steel, or concrete is used will determine the project’s lifespan and energy efficiency. Proper rough framing practices are crucial; thus, safe, functional, and aesthetically pleasing buildings form the foundation for solid construction businesses.

Tony Cummins began his career as a carpenter in a sawmill, where he learned the ins and outs of cutting and processing wood. Over the years, he honed his skills and gained vast knowledge about different types of lumber and their uses. After many years of working directly in the industry, he decided to start his company for preparing lumber takeoffs to help contractors.